Solutions

Engineered Solutions. Flexible Systems. Consistent Reliability.

Scout Surface Solutions provides engineered equipment systems built for high-efficiency completions. Our products are designed for adaptability, reliability, and safe performance across a wide range of frac environments. With in-house engineering capabilities, we model site layouts, deliver custom drawings, and continuously develop new solutions—supported by a growing portfolio of patented technologies. From simulfrac and trimulfrac to split stream and leapfrog operations, Scout has never failed to execute, even with limited lead time or complex configurations. All rig-up and rig-down is handled by Scout personnel, allowing for clean handoffs, fewer variables, and consistent performance. We also interface directly with frac rental companies to reduce complexity, cost, and coordination burden for our customers. Whether you need engineered systems or a fast, flexible response in the field, Scout delivers solutions that are built to work—and backed by experience.

Call Us At (817) 396-4404

Call Us At (817) 396-4404

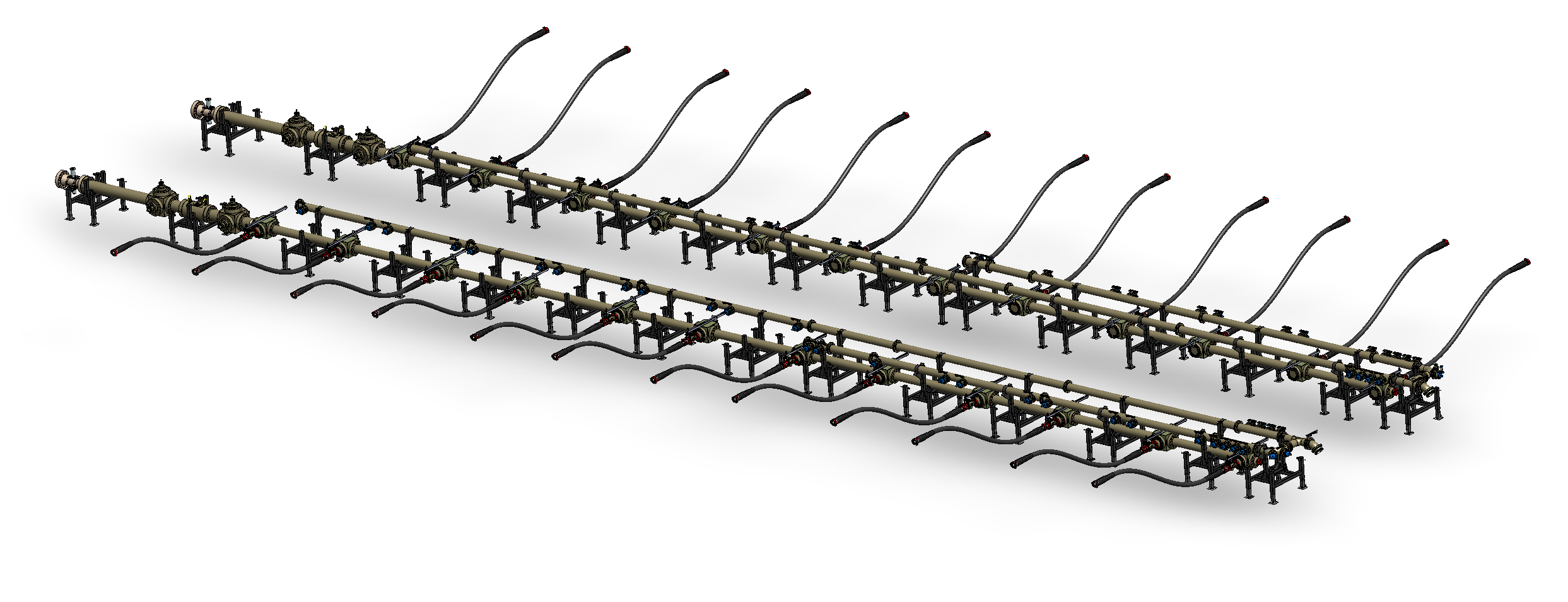

Monobore Manifold Systems

Designed for high-volume, high-efficiency completions, Scout’s monobore systems offer simplified rig-up, flexible configurations, and reliable performance across simulfrac, trimulfrac, and complex low-pressure system layouts, as well as full leapfrog capability.

Modular design allows quick reconfiguration for pad-specific requirements

Simplified layout reduces rig-up time and HSE risk

Built with API components and high-spec materials for durability

Lightweight, transport-efficient design for faster deployment

All rig-up and rig-down handled by Scout field teams

Scout can provide all equipment from fluid end to wellhead

Scout supports rentals of 1502 iron, frac hoses, and individual monobore API components

Complex Frac Systems

Our teams are exceptionally capable in complex operations and can scale up or down to meet unique job needs including simulfrac, trimulfrac, quadfrac, and continuous frac. Scout’s modular monobore designs allow equipment and pumps to be arranged efficiently without compromising safety or performance.

Fit-for-purpose design that reduces equipment sprawl

Flexible pump and valve arrangements based on customer layout

Engineered to simplify flow paths and maximize uptime

Supports electric or conventional fleets

Low pressure system using patented Uni-Line technology

Customizable Low-Pressure Systems

Scout’s custom and patented low-pressure systems excel in complex applications, including split stream, and are configurable for any pump or pad spacing requirements. Split stream systems are designed to isolate clean and dirty fluid lines, improving maintenance scheduling and equipment longevity for our customers.

Split stream configuration enables pumps to run sanded and non-sanded fluid simultaneously and reduces wear on high-value components

Scout’s patented Uniline system maximizes flow to every pump on location and prevents sanding off of low-pressure lines

Compatible with flexible missile layouts

Leapfrog Systems (Pump and Go)

Scout’s systems come with guaranteed leapfrog capability, which allows us to rig up a fresh monobore on the next location instead of moving equipment from pad to pad. This reduces mobilization bottlenecks, expedites pad moves, and saves customers money.

Reduces HSE risk and exposure

Keeps monobore off the critical path during mobilization

Reduces location congestion by minimizing shared equipment use

Allows Scout crews to work independently of fleet move schedules

Proven to reduce move times for frac fleets between pads

All equipment comes back to a Scout facility after every job for inspection, resulting in higher performing equipment and reduced NPT

Monobore Manifold Systems

Designed for high-volume, high-efficiency completions, Scout’s monobore systems offer simplified rig-up, flexible configurations, and reliable performance across simulfrac, trimulfrac, and complex low-pressure system layouts, as well as full leapfrog capability.

Modular design allows quick reconfiguration for pad-specific requirements

Simplified layout reduces rig-up time and HSE risk

Built with API components and high-spec materials for durability

Lightweight, transport-efficient design for faster deployment

All rig-up and rig-down handled by Scout field teams

Scout can provide all equipment from fluid end to wellhead

Scout supports rentals of 1502 iron, frac hoses, and individual monobore API components

Complex Frac Systems

Our teams are exceptionally capable in complex operations and can scale up or down to meet unique job needs including simulfrac, trimulfrac, quadfrac, and continuous frac. Scout’s modular monobore designs allow equipment and pumps to be arranged efficiently without compromising safety or performance.

Fit-for-purpose design that reduces equipment sprawl

Flexible pump and valve arrangements based on customer layout

Engineered to simplify flow paths and maximize uptime

Supports electric or conventional fleets

Low pressure system using patented Uni-Line technology

Customizable Low-Pressure Systems

Scout’s custom and patented low-pressure systems excel in complex applications, including split stream, and are configurable for any pump or pad spacing requirements. Split stream systems are designed to isolate clean and dirty fluid lines, improving maintenance scheduling and equipment longevity for our customers.

Split stream configuration enables pumps to run sanded and non-sanded fluid simultaneously and reduces wear on high-value components

Scout’s patented Uniline system maximizes flow to every pump on location and prevents sanding off of low-pressure lines

Compatible with flexible missile layouts

Leapfrog Systems (Pump and Go)

Scout’s systems come with guaranteed leapfrog capability, which allows us to rig up a fresh monobore on the next location instead of moving equipment from pad to pad. This reduces mobilization bottlenecks, expedites pad moves, and saves customers money.

Reduces HSE risk and exposure

Keeps monobore off the critical path during mobilization

Reduces location congestion by minimizing shared equipment use

Allows Scout crews to work independently of fleet move schedules

Proven to reduce move times for frac fleets between pads

All equipment comes back to a Scout facility after every job for inspection, resulting in higher performing equipment and reduced NPT

Frac Hoses and Connections

Scout provides a wide range of hoses and connection systems for rental to meet site-specific requirements, reduce iron, and support extended reach.

Over 1,000 hoses in inventory for rental

Large and small bore hoses with internal dimensions (ID) sizes from 2" to 5"

Hose lengths include 7 ft, 10 ft, 13 ft, 15 ft, 20 ft, and 25 ft

Sourced from multiple manufacturers to match customer preference

Ideal for reducing rig-up complexity and pad congestion

Multiple style end connections

Scout supports rentals of 1502 iron and individual monobore API components

Reach out to us for more connection types.

Pressure Control Systems

Our pressure relief and bleed-off systems, Sentinel PR and Guardian, are engineered for performance, safety, and long service life under demanding frac conditions. Both of these valves can be operated together with one tablet and monitored remotely.

SENTINEL PR - Pressure Relief Valve

Our proprietary, engineered pressure relief valve is mounted on top of the monobore to reduce footprint on location, removes multiple leak points, and eliminates the opportunity for sand fallout in other lines.

Integrated pressure and position sensors, operated via tablet in the data van

Digital logging and remote operation capability

Compatible with API 6A, NACE MR0175, SIL Level 3

3" orifice with full discharge volume

Tungsten carbide wear components

Field-serviceable; designed for efficient interface

GUARDIAN - Bleed-Off Valve

Our proprietary, engineered bleed-off valve features a footprint-reducing design that mounts directly on the monobore, simplifying the system layout while reducing sand fallout in other lines and preventing potential leak points.

Automated frac bleed-off, operated via tablet in the data van

Digital position indicator included

Hydraulic piston-operated for fast flow control

Adjustable control of bleed-off speed

Built for high-solids, abrasive environments

API 6A PSL-3, NACE MR0175 compliant

Available in 1.5" and 2" trim

Extended Reach Systems

Scout’s monobore and flexible connection systems enable frac operations on remote or offset pads without compromising flow or safety. Our solutions can accommodate complex terrain such as elevation changes and topographical challenges.

Enables well completions at greater distances from pumping equipment

Reduces the need to relocate full equipment spreads

Scout’s iron and Monoflex® hose systems enable reliable extended reach operations

Lowers cost and complexity of remote completions

Proven performance across multiple basins and site conditions

Reach Out To Us Today